Heavy Lifting News

Case Studies on Innovative Problem Solving

Assembling Blue Origin’s New Glenn Rocket

09/11/2025

For years, Engineered Rigging (ER) has been the go-to for supply of complex heavy lifts, from delicate flight simulators to massive power transformers. But our mission took on a whole new dimension when we were called to help the Blue Origin team at Cape Canaveral. This project wasn’t just about weight; it was about precision on a cosmic scale, as we provided the mission-critical equipment to assemble the next generation of space travel, namely Blue Origin’s New Glenn rocket.

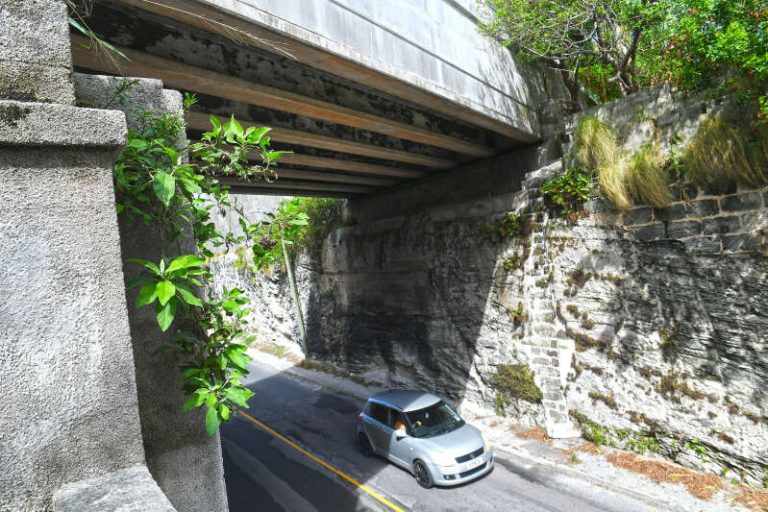

Blue Origin chose a site with a legendary past to build its future. Launch Complex 36 (LC-36) at Cape Canaveral Space Force Station, once the home of over 140 NASA launches for missions like Mariner and Pioneer, lay dormant for a decade after its final launch in 2005. Now, a new era has begun.

Founded by Jeff Bezos, American space technology company Blue Origin leased the site for its New Glenn rocket, named after John Glenn, the first American to orbit Earth. According to Blue Origin, New Glenn is a “giant, reusable rocket built for bigger things” that will use cleaner fuel and lead to significantly less waste and cost. The company invested more than $1 billion to renovate the launch complex from the ground up to house New Glenn’s launch pad, vehicle integration, first stage refurbishment, propellant facilities, and environmental control center. (source: Blue Origin)

With the groundwork in place, Blue Origin prepared for the vehicle integration process which involves assembling the spacecraft. At more than 320 feet tall (roughly the height of a 30-story building) with a diameter of 23 feet, New Glenn is one of the largest vehicles ever built. It features a seven-meter payload fairing, enabling twice the volume of standard five-meter class commercial launch systems. To put it into perspective, the cargo space can hold three school buses.

Given the massive size of the rocket, a highly accurate heavy lifting machine was required to connect stage 1 and stage 2 of the rocket during the vehicle integration process. The first stage, which is reusable, is 189 feet tall and weighed 44,000 pounds empty. The second stage is 77 feet tall with a reported weight of 18,000 pounds empty.

Blue Origin contacted the Engineered Rigging team to discuss an Enerpac Synchronous Hoist System (Synchoist) as the potential candidate for manipulating the heavy structures. A Synchoist is a below-the-hook device, also known as sling adjuster or hydraulic turnbuckle, that allows a single crane to precisely position heavy and/or unbalanced loads. A typical system includes multiple cylinders mounted in line with the rigging and a hydraulic unit with controls (manual or electronic) to precisely raise or lower cylinders to the desired orientation.

After careful consideration, the Blue Origin team selected a rental Synchoist system from the Engineered Rigging rental fleet. Upon mobilization of the equipment and some specialized training, Blue Origin used the hydraulic cylinders to make minute adjustments while mating the rocket stages, a level of control not available with previous systems.

The rental system performed well, and Blue Origin ultimately purchased a customized Synchoist System. This system featuring computer control, stroke encoders and load readout, will be used during the vehicle integration every time a New Glenn rocket is prepared for launch. In addition to the equipment, Engineered Rigging provided engineering, training, technical support and custom fabrication for the Blue Origin project.

On February 21, 2024, the New Glenn rocket was debuted on the new LC-36 launch pad. After a comprehensive test campaign, the rocket was successfully launched on January 16, 2025. It safely reached its intended orbit during the mission which was dubbed NG-1.

Featured Equipment

- 2 custom Hydraulic Cylinders: 110-ton capacity each

- Split flow Pump

- 25m hoses

- Computerized Control system