Heavy Lifting News

Case Studies on Innovative Problem Solving

Moving a Million Pound Machine

06/16/2024

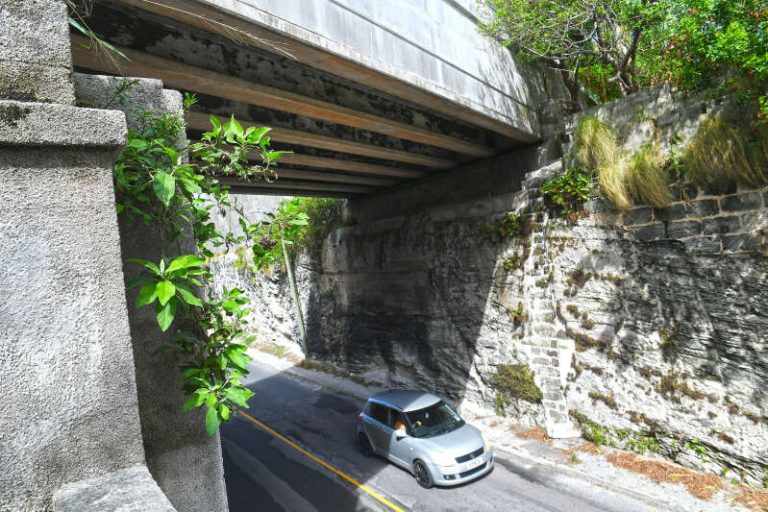

While Belger Cartage Service has a century of heavy lifting experience under its belt, a recent project presented an unprecedented challenge. Before construction could proceed on a new manufacturing facility In Tulsa, Okla, a massive autoclave needed to be moved into position. An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure. This particular autoclave was designed to cure composites for airplane parts. It weighs an epic million pounds, is 55 feet long and 25 feet wide.

Upon delivery to the construction site, the autoclave was placed in an out of the way location that would require two separate lateral moves to align the machine to the eight pylons which were the machine’s foundation. A total of more than 50 feet of lateral movement was needed, including a portion at elevation over the approximately 5.5 feet deep pit where the pylons were located. Once positioned, the building would be constructed around the massive autoclave. Belger approached Engineered Rigging to design the lift plans, provide equipment rental and deliver onsite technical support.

“Having multifaceted capabilities under one roof, Engineered Rigging was able to fulfill Belger’s needs within the required six-week deadline,” explained John Kuka, Director of Business Development for Engineered Rigging (ER).

The Engineering Plan

When developing the plan, several factors were considered by ER’s engineering team including the load weight, dimensions, lifting points, depth of the pit, center of gravity and site conditions.. Ultimately, Engineered Rigging determined that two Enerpac LH400 Low-Height Skidding Systems were the ideal solution for the lateral moves. By doubling the track on each skidding system (see image 1), the load capacity was doubled to safely skid the million pound weight of the autoclave. The skidding systems were powered by two Enerpac SFP421SJ Split Flow Pumps while Enerpac HCR20010 Double-Acting Hydraulic Cylinders were used to lift and lower the autoclave onto the foundation.

The first lateral move was 21 feet from west to east. After it was completed, Engineered Rigging’s technicians lifted the autoclave to reset the skidding systems and track to traverse north to south. The autoclave was then slid another 32 feet.

Once in position above the support foundation, a precise sequence of stage lowering was followed using a combination of the Enerpac 200-ton cylinders with a 10 inch stroke, load stools and cribbing to jack and crib the autoclave down into its final elevation (see image 2).

Rapid Response to Unexpected Site Challenges

While the equipment was standard, the site offered its share of challenges. A pre-move site inspection by Engineered Rigging’s onsite technicians revealed that the elevation along the transit path was uneven. For the Low-Height Skidding System to operate safely and efficiently, the track must be level. Engineered Rigging provided crane mats to level the track. Another issue involving ground conditions arose when the first lateral move began atop a concrete parking lot. The weight of the autoclave caused the concrete to buckle.

“Unfortunately, site conditions differed from the design drawings and the reported allowable load-bearing of the concrete was inaccurate. We halted the job and our site team and engineers evaluated the situation. We quickly obtained an emergency load of 16 steel road plates, which distributed the weight over a larger area and protected the concrete,” explained Kuka.

Once the first lateral move was completed, Engineered Rigging’s technicians reset the system and the second lateral move was performed. After 4 days, the autoclave was safely in its final resting position and the construction of the building commenced.